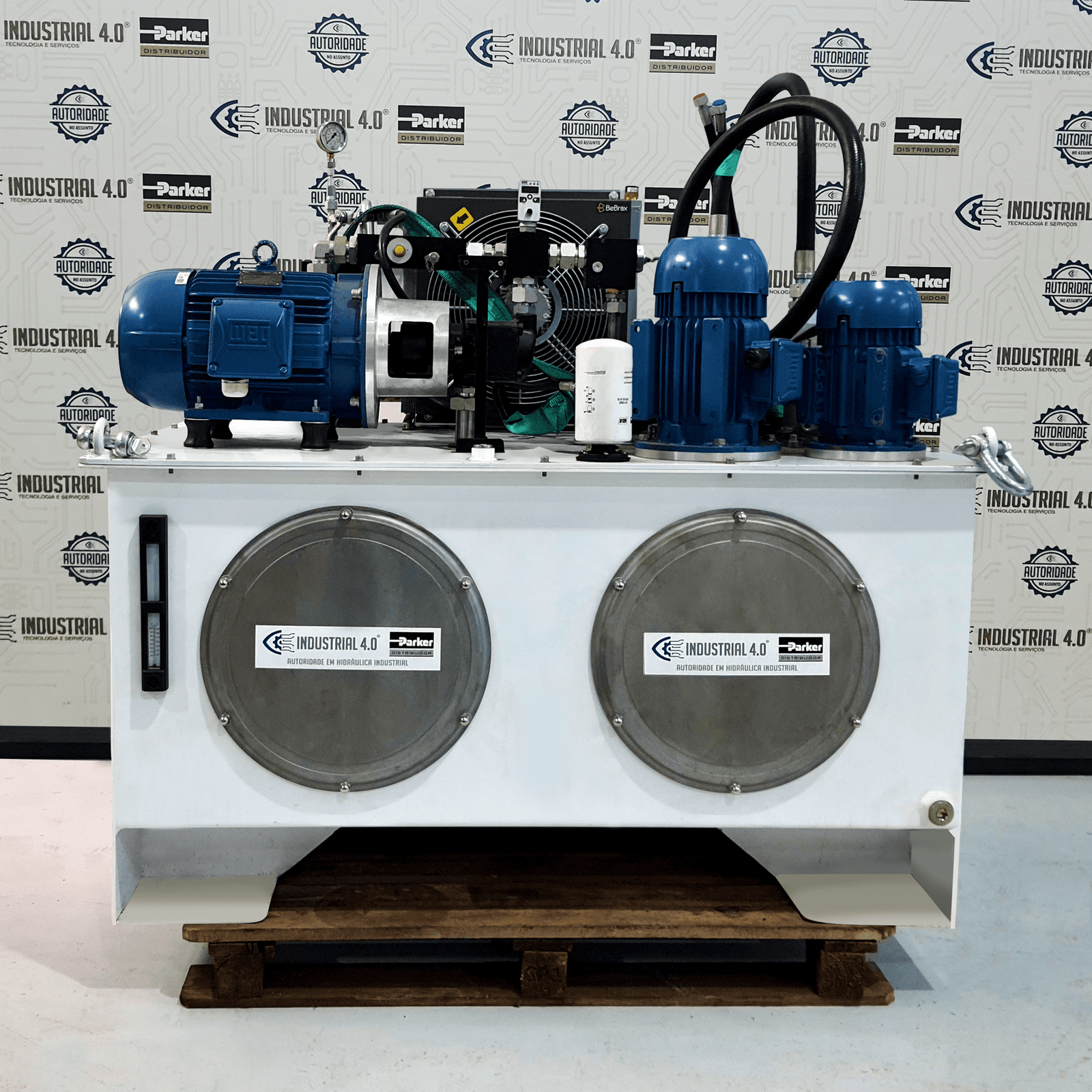

The INDUSTRIAL 4.0 Hydraulic Flushing Unit was custom-built for performing flushing in industrial hydraulic systems.

This hydraulic flushing unit was developed by INDUSTRIAL 4.0 using Parker technology. The unit is capable of performing flushing, hydrostatic testing, functional testing, and oil filtration — all with the same equipment.

APPLICATION

The INDUSTRIAL 4.0 hydraulic flushing unit is ideal for service providers and industries seeking a high-quality piece of equipment ready to efficiently perform hydraulic flushing whenever needed.

In summary, the hydraulic flushing process consists of the forced circulation of fluid at high flow rates through the entire hydraulic system. Therefore, a robust hydraulic unit is an essential component in this process.

Hydraulic flushing is recommended in several situations, such as:

After the installation of new hydraulic systems

After replacing critical components such as pumps or valves

During corrective or preventive maintenance shutdowns

To eliminate accidental system contamination

After long periods of inactivity

If you work with industrial hydraulic equipment, investing in a unit like this makes perfect sense.

“We developed this unit to use in our own flushing service operations. The results were excellent — it’s tested and approved.”

— Eng. Eduardo Bianchese, INDUSTRIAL 4.0

SPECIFICATIONS – INDUSTRIAL 4.0 HYDRAULIC FLUSHING UNIT

System for flushing pipelines with internal diameters up to 50 mm using fluid with 10 cSt viscosity

Electrical control panel with frequency inverter to adjust the correct flushing flow rate according to pipeline diameter

15 HP installed power, compatible with 220V/380V/440V three-phase systems

Particle counter for measuring the number of particles in the fluid, with digital readout according to NAS and ISO standards

High-efficiency hydraulic filters for fluid cleaning, with 10-micron and 2-micron options and visual saturation indicator

Electronic pressure sensor with digital display for pressure measurement during tests

Hydrostatic testing system up to 300 bar, with visual pressure indication and high-quality pressure regulation valves

Air cooling system for fluid temperature control

BENEFITS

Multifunctionality in a single piece of equipment

Performs flushing, hydrostatic testing, functional testing, and oil filtration.

High efficiency in contaminant removal

Ensures deep cleaning of the hydraulic system, removing solid particles, sludge, and metallic residues.

Reliable technology with Parker components

Greater durability, performance, and operational safety.

Field-tested equipment

Used in INDUSTRIAL 4.0’s own service operations, with proven results.

Time and operational cost savings

Reduces hydraulic system failures and prevents unexpected corrective maintenance.

Easily adaptable to different systems

Compatible with pipelines up to 50 mm and various types of fluid.

Precise and safe control

Electric control with frequency inverter, digital pressure sensor, and high-quality valves.

Real-time fluid quality monitoring

Digital particle counter with readings according to NAS and ISO standards.

Integrated cooling system

Keeps fluid temperature stable, ensuring continuous efficiency.

Ideal for various maintenance scenarios

Recommended for new installations, component replacements, preventive shutdowns, and reactivations.

Interested? Get in touch now to learn more!